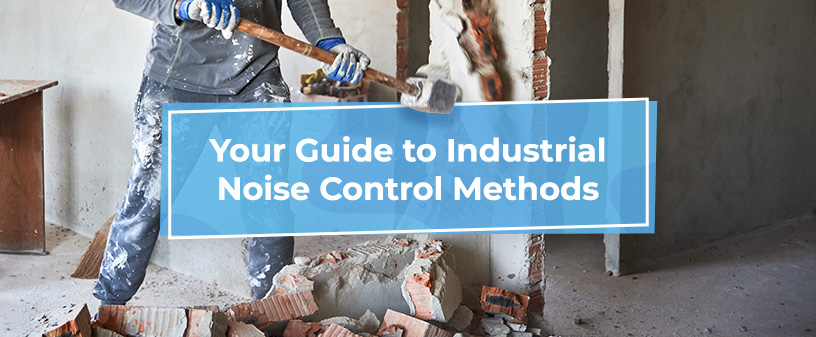

Industry makes the world go around. From manufacturing to energy, we rely on industry to keep us clothed, fed and powered up. But progress can be noisy. Roaring heavy machinery, clattering tools and humming ventilation systems make a distracting symphony. Excessive noise is more than a nuisance. It can affect workers’ well-being. Industrial noise leads to fatigue, difficulty concentrating or long-term hearing damage. Controlling noise protects those who contribute to these vital sectors.

Industrial building owners or managers seeking ways to tame industrial noise, read on. This guide gives you the scoop on curbing noise levels for a happier, more harmonious workplace.

What Is Industrial Noise?

Industrial noise is generated by factories, construction sites and manufacturing plants. Equipment, heavy machinery or processes produce excessive noise. These noises represent the drive for productivity but can damage human health and the environment. That is why this sound is also referred to as industrial noise pollution. Like air or water pollution, noise pollutes surrounding ecosystems. The National Environment Agency and Occupational Safety and Health Administration (OSHA) set decibel (dBA) limits for industrial noise control and acoustics.

Types of Industrial Noise

In industrial settings, noise travels through air, structures, fluids or mechanics. Here are the four types of industrial noise:

- Airborne: Sound waves travel through the air before hitting your ears. Examples of airborne sounds include buzzing conveyor belts or whirring machinery.

- Elasticity: Materials under mechanical stress expand, contract and change shape. These materials emit sound as they reform. Think of the sound of an elastic stretching and then snapping back.

- Fluid: The vibration of movement through liquids or gases can make noise. Gas swishing through pipes or steam hissing from heavy machines produce industrial noise.

- Impact: Structure-born or impact noise happens when objects collide. Sound transmits through walls, floors and ceilings. Examples of impact noise include clanging metal or pounding jackhammers.

Common Industrial Noise Examples

Industrial noise ranges from 40 dBA for an office to over 130 dBA for construction equipment. Take a look at these examples of noises found in industrial environments:

- Construction activity: Operating heavy machinery, drilling and hammering are high-decibel activities.

- Equipment noise: Industrial sites use noisy equipment. Think high-pitched squeals from rotating machines or the screech of metal against metal.

- Transportation centers: Planes taking off, trains stopping and ships docking make an almighty racket.

- Power plant noise: Generators, compressors, turbines and other machines lack the ability to whisper.

- Quarries and mines: From blasting to crushing, mining is a deafening business. The booming activities can disturb nearby residential areas.

- Manufacturing: Processes involved in everything from chemical to textile production make industrial noise.

Methods for Industrial Noise and Vibration Control

Now that you understand the how, why and what of industrial noise, let us dive into ways to control it. The trick is knowing the source and type of sound. A good starting point is differentiating between soundproofing and sound absorption. Soundproofing materials trap sound waves, stopping them from escaping into another space. Sound-absorbing materials soak up sound energy to improve the acoustics within a room.

Industrial sound-dampening products should have a sound transmission class (STC) rating of 30 or more. The STC rating is a material’s ability to prevent sound transmission, ranging from 25 to 65.

Take control of noise in your industrial space with these methods and products.

1. Soundproofing Barriers

A soundproofing barrier does exactly what its name says — it creates a barrier to stop sound. The foam, vinyl or fiberglass in these barriers repel sound energy and vibration. You can install these easy-to-use barriers on pipes, drywall or inside machinery.

Here are some industrial-grade acoustic barriers:

- Fiberglass composites: A product like Quiet Barrier® Lag is ideal for industrial settings. It combines Quiet Barrier® soundproofing material, a fiberglass blanket and reinforced polyester facing. Use this Class A™ soundproofing superstar for noisy machines, pipes, valves or ducts.

- Mass loaded vinyl (MLV): This material provides tough, effective sound-deadeninging mooo-gic! With an STC rating of 32, Quiet Barrier® HD Soundproofing Material tackles even the most distracting sounds. The nonporous material is as dense as it is flexible. You can attach it to joists or studs and seal it with soundproofing tape.

- Temporary barriers: Sometimes, you need a quick and portable sound solution. Enter acoustic quilts! These blankets pack a soundproofing punch when laid over (or under) noisy equipment. Choose from different sizes of Quiet Barrier® Acoustic Quilts to suit your needs.

2. Acoustic Panels

Acoustic panels use dense, sound-absorbing materials to suck up sound waves. These panels reduce echo and unwanted noise and come in various options. Acoustic fiberglass transforms sound energy into heat through thermal isolation. The Acoustic Glass Mineral Wool 2″ blocks machinery noise while improving internal acoustics. You can use these panels to create a wall or insulate rooms for quieter equipment operation.

Fabric-wrapped panels like the Udderly Quiet® range offer power and visual appeal. They look as good as they work. You can customize these panels to your brand while meeting building code requirements. Or, for industrial noise control on a budget, consider acoustic foam panels. Choose sustainable, 80% recycled cotton Echo Absorber™ Acoustic Panels for a greener option.

Industrial facilities often contend with fire or water exposure risks. Never fear — fire-rated and water-resistant panels are here! Our Class A™ Acoustic Foam Panels maintain sound absorption in temperatures up to 482 degrees Fahrenheit. Say goodbye to water damage with Quiet Board™ Acoustic Panels. Their sturdy styrofoam construction keeps soaking up sound, come rain or shine.

3. Sound-Dampening Materials

Are you dealing with a hollering HVAC, chaotic compressors or jolly loud generators? Sound-dampening materials save the day — and your ears. Sound-deadening “kills” industrial machine vibrational energy by absorbing shock. Apply easy-stick Vibra Block Sound Deadening Material on the offending surface. Get Vibra Block in pads, strips or sheets to suit your space.

Silent Running Soundproof Coating is an odor-free paint that reduces reverb by transforming sound into heat. And speaking of heat, it resists up to 250 degrees Fahrenheit!

Industrial Noise Control Benefits

Industrial noise pollution impacts worker health, community well-being and the environment. Chronic exposure to sounds over 85 dBA can damage hearing and lead to hearing loss. Many industrial noises exceed the recommended noise levels of 70 dBA or below. Consider these benefits.

Improves Employee Health

Limiting noise can protect your workers from hearing loss and other health issues. Lower noise levels also reduce stress and anxiety, enriching mental well-being. A quieter workplace can even help your employees sleep better!

Increases Productivity and Efficiency

A quieter work environment is a more productive work environment. Fewer noise distractions improve employees’ ability to concentrate, communicate and complete tasks. Plus, employees are less likely to make mistakes. You enjoy increased work quality, greater operational efficiency and shorter production times.

Complies With Regulations

Regulatory bodies like OSHA set strict rules for occupational sound levels. For noise exposure over 85 dBA, OSHA requires hearing conservation programs. High-noise construction and demolition industries have specific regulations. Business owners who take appropriate measures can meet these standards. Investing in soundproofing can save costly penalties or lawsuits. If in doubt, drown that sound out!

Boosts Employee Morale

Creating a comfortable environment increases job satisfaction. Happy employees tend to stick around longer and take less sick leave. Plus, an organization known for maintaining a healthy workplace attracts better talent.

Fosters Community Relations

Noise consideration can foster better community relationships and a positive public image.

Reduces Noise Pollution

Controlling noise pollution contributes to sustainability. It can even form part of your business’s corporate social responsibility initiative. The birds, bees, flowers — and cows — will thank you!

Give Industrial Noise the Hoof With Soundproof Cow

Industrial processes should be seen, not herd. Take control of unwanted noise in your factory, plant or facility with top-quality products from Soundproof Cow. Browse our easy-to-use soundproofing materials or peruse our sound-absorbing superstars. Not quite sure where your industrial noise is coming from? Fill in an online contact form to ask a question or get a free acoustical analysis, no bull, no fuss!