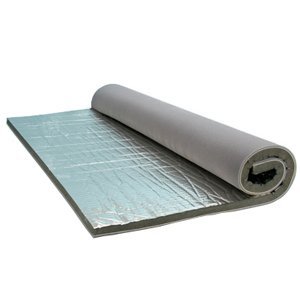

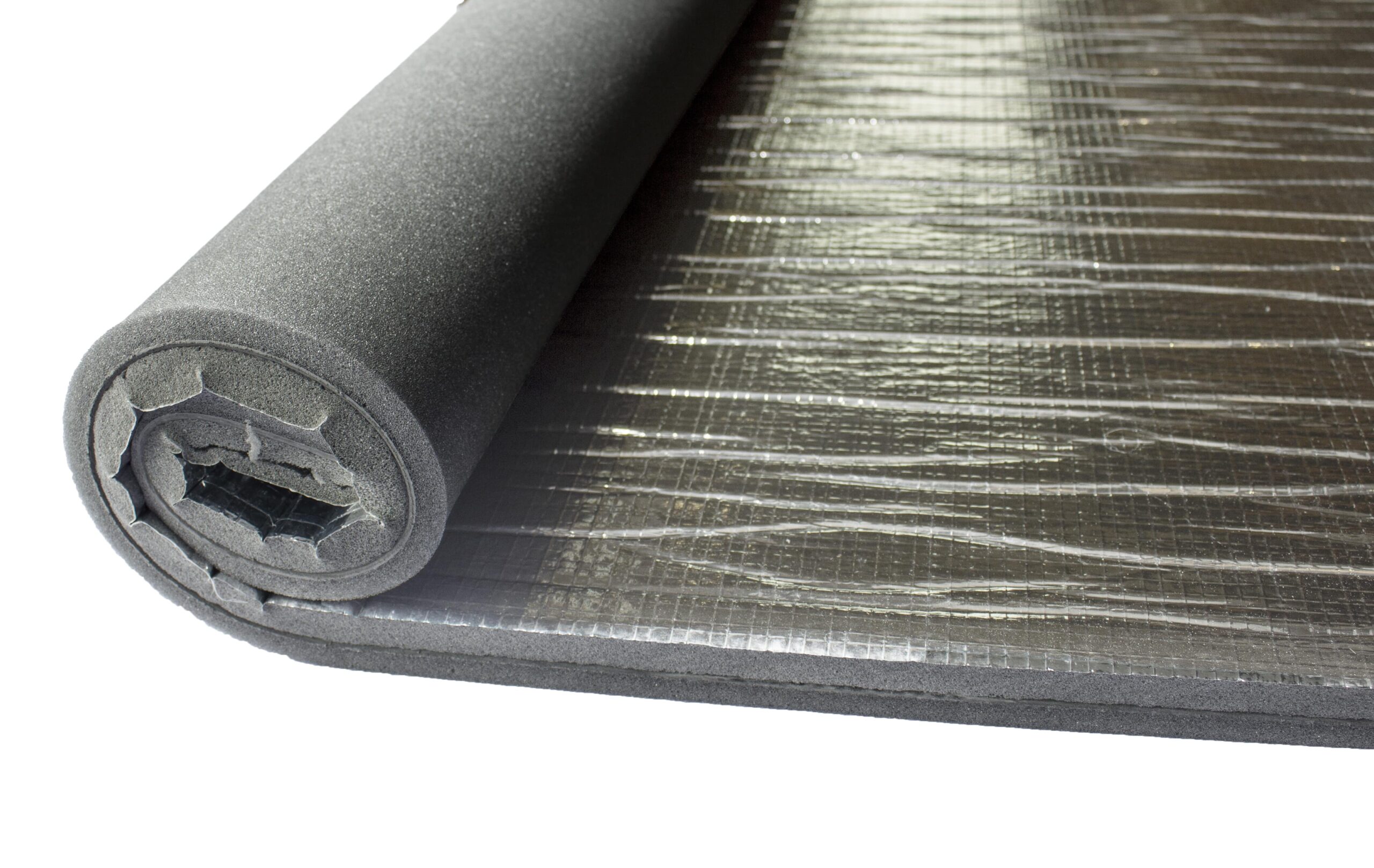

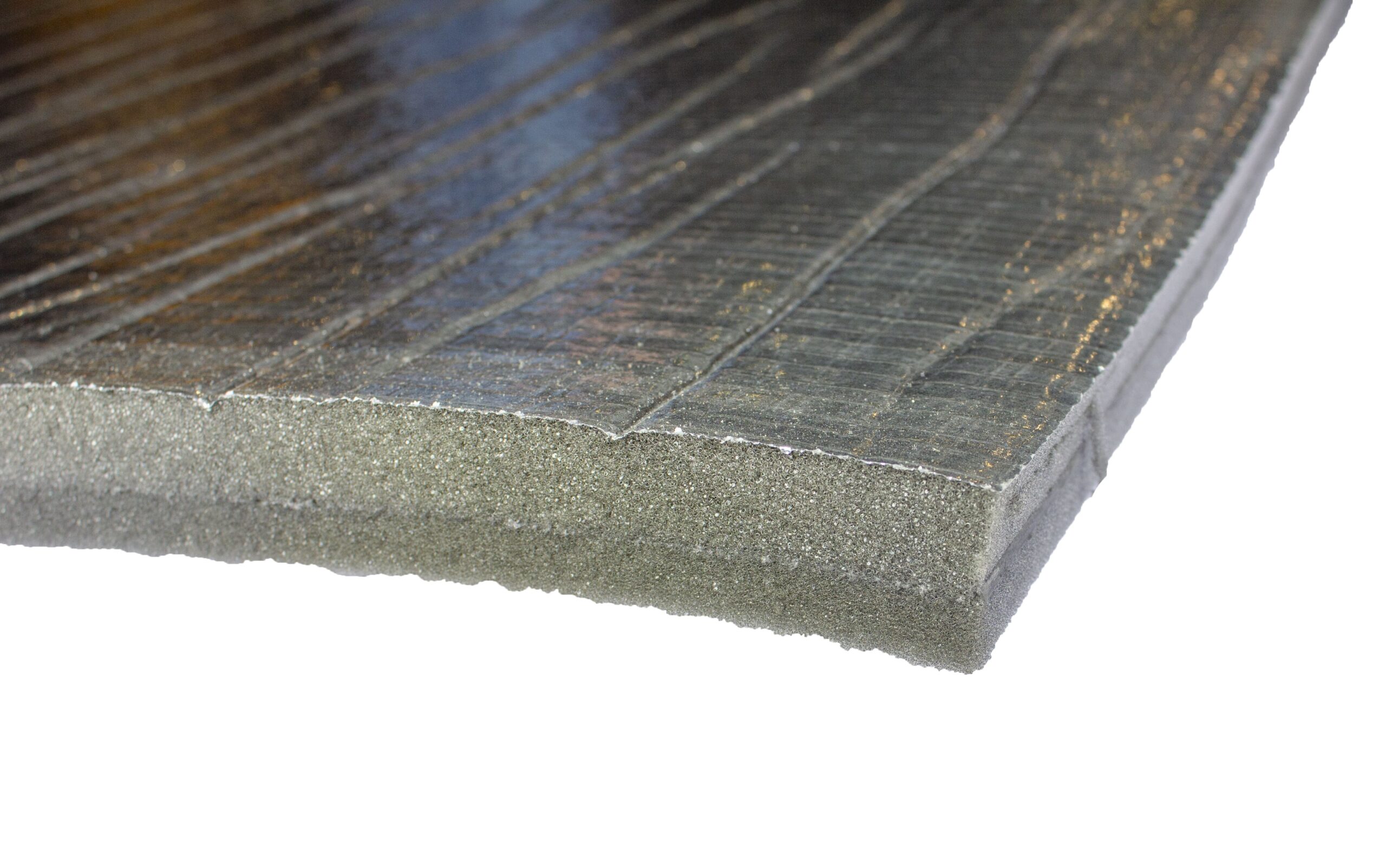

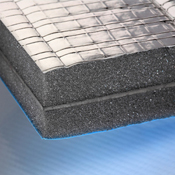

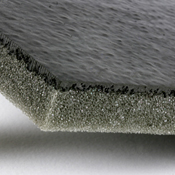

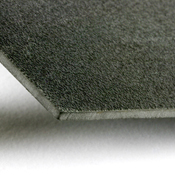

Triple Soundproofing Function — The mass of the Quiet Barrier® layer blocks sound while its flexible nature dampens sound energy. The thicker of the two layers of Acoustic foam acts as a sound absorber, decreasing ambient reflected noise. The thinner layer of acoustic foam acts as a decoupler, structurally isolating the heavy barrier layer from the construction assembly, ultimately decreasing vibration and increasing the sound blocking performance.

Heat Resistant — Quiet Barrier® Specialty Composite has a fiber reinforced Polyester Film facing that not only reflects high frequencies but also reflects heat back towards the source. This product is our best performing sound blocking material in exposed locations with above average temperatures.

Durable — The Polyester Film facing provides a cleanable, tear resistant surface for applications that may come in contact with oils or grease. Once punctured, the embedded fibers will prevent additional tearing or damage. The acoustic foam and barrier layers are thermally bonded, providing a much stronger, longer lasting bond over traditional adhesives.

Low Profile — Quiet Barrier® Specialty Composite has a thickness of 1 1/4 inch, saving valuable square footage. Quiet Barrier® Specialty Composite is used in many equipment enclosures where space is tight.

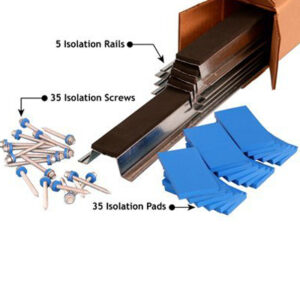

Ease of Installation — Quiet Barrier® soundproofing composite is available with an optional “peel and stick” pressure sensitive adhesive (PSA). Simply peel the silicone coated paper backing and place the product where it is needed.

In-stock — We stock a large amount of Quiet Barrier® Specialty Composite in all advertised sizes and configurations. Most products are shipped the same day they are ordered and arrive at your project in three business days.

Customization — We will create a custom Quiet Barrier® Specialty Composite for your application. Custom profiles, shapes and sizes can be quoted upon request. For custom Quiet Barrier® Specialty Composites there are minimum order quantities, please contact our Acoustic Consultants for more information!

Flammability — Quiet Barrier® Specialty Composite contains polyurethane foam that has a flammability rating of UL94 HF-1. Before choosing this product, be sure the flammability rating passes your local building code for exposed materials.

Sound Test

See how our Quiet Barrier® Specialty Composite produced great results for a happy customer!

Product Availability

Also available in Quiet Barrier® Specialty Composite w/PSA

Special Order Sizes and Thicknesses are available.

For details, call 1-866-949-9COW.

Details

Construction Industry:

- Air Conditioning Unit Enclosures

- Computer and Server Rooms

- Compressor Enclosures

- Equipment Rooms and Enclosures

- Generator Enclosures

- HVAC Cabinets

- Industrial Facilities

Automotive Industry:

- Hood and Trunk Liners in Automobiles

Heavy Equipment Industry:

- Engine Compartment liners

- Cab Liners

- Floor liners

- Hood and Trunk Liners

Marine Industry:

- Engine Compartment liners

- Hatch Cover liners

- Hull Liners

How Quiet Barrier® Specialty Composites work

In essence, Quiet Barrier® Specialty Composite products block the transmission of noise from one area to the next. The sound from the “noise source” hits the Polyester Film facing and high frequencies are reflected back towards the noise source. Some of the sound is then absorbed by the acoustic foam. The sound that penetrates the acoustic foam layer is then blocked by the decoupled barrier layer and reflected back into the room or space of origin. See figure 1. The difference between the source noise and the transmitted noise is the sound transmission loss.

Polyurethane Foam Warning

All Polyurethane Foams, including Combustion Modified Foams, will burn. Do not expose to any flame source. Once ignited, they can produce rapid flame spread, intense heat, dense smoke and toxic gases causing death. Warnings should be given to your employees and or customers. Test data does not necessarily reflect a foams performance under actual fire conditions. Before purchasing any foam, be sure to check with your local code officials to confirm the required flammability rating of exposed materials for your area.

Cautions and Limitations

Before applying this product all surfaces must be dry and clean, free of any grease or oil.